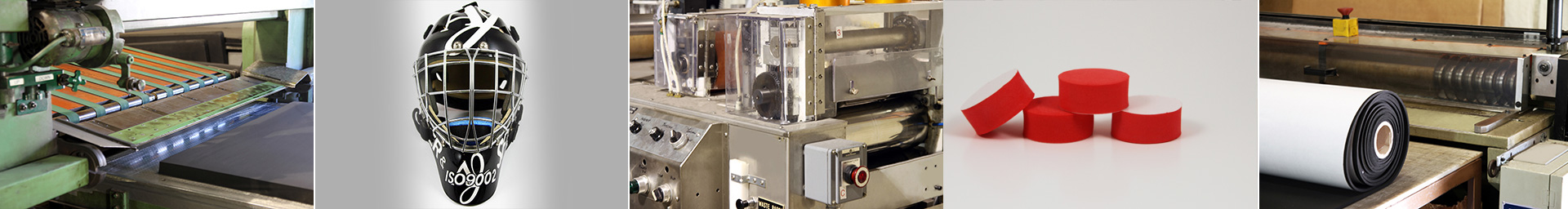

Rubber Gaskets

A.J. Rubber & Sponge Ltd. manufactures the majority of its gaskets and seals from various types of rubber materials including:

- SBR (styrene butadiene rubber)

- Nitrile rubber

- Cloth inserted rubber

- Silicone rubber

- Military specification rubber

- EPDM (ethylene propylene diene monomer rubber)

- Neoprene rubber

- Buna-n rubber

- EP (ethylene propylene rubber)

- Butyl rubber

- Natural rubber

- Fluorocarbon rubber

Each of the above listed materials are best suited for varying sets of circumstances and parameters. Such factors can include:

- Temperature ranges

- Exposure to harsh chemicals (ie. hydrocarbons)

- Abrasion

- Ultraviolet (UV) light exposure

Rubber materials also possess a number of intrinsic characteristics:

- Compression set

- Flange load

- Tensile strength

- Rubber aging

The rubber gasket manufacturing industry often uses fillers and additives to achieve the aforementioned properties. Available in both natural and synthetic form, rubber is the material of choice for the fabricators of sealing and gasket materials due to its unrivaled ability to reform to their original state even after the application of an exterior depressing, compressing or deforming force. This characteristic is also directly related to the tensile strength of various kinds of rubber. Rubber is better suited for low temperature applications than high temperature ones, and is most suitable for gaskets that operate in a medium temperature range (so that both the shape and functionality of the rubber gasket are preserved).

At A.J. Rubber & Sponge Ltd., we help customers select from the many choices of rubber material available to them in order to ensure that they have the best rubber gasket material for their seal or gasket application. One thing we always emphasize is that of the many types of rubber gasket and rubber seal materials available, each has its own set of unique characteristics. The majority of rubber gaskets or seals used in commercial settings are comprised of a rubber called SBR (also known as red rubber), and is the most common type of rubber seal/gasket we manufacture. A.J. Rubber & Sponge Ltd. stocks, and can source, many different kinds of rubber materials, ensuring fast turnaround times for the production of custom seals and custom gaskets for any industry. Our experienced and courteous team will happily work with you to ensure that you have selected the optimal rubber gasket material for your sealing and gasket requirements.