Nitrile Rubber Gaskets

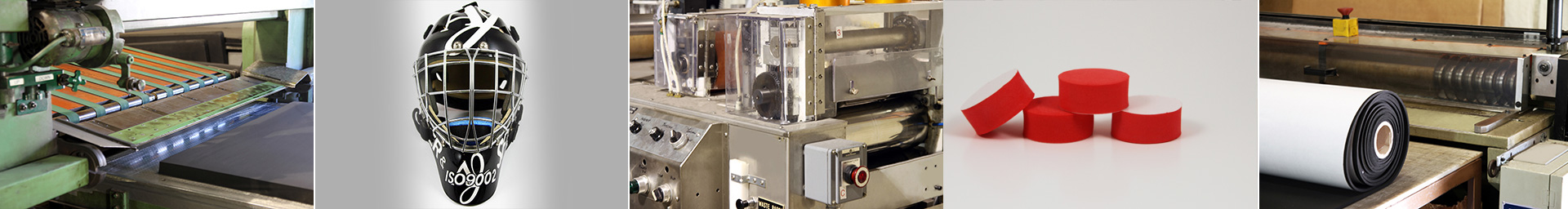

A.J. Rubber & Sponge Ltd. has a long history of manufacturing custom die cut and custom kiss cut rubber gaskets, and has even custom fabricated NBR (acrylonitrile butadiene rubber) gaskets for use across various types of industries. Although some of the rubber gaskets we produce are comprised of natural rubber, nitrile rubber belongs to a family of synthetic rubber gasket materials that are made up of a copolymer of butadiene and acrylonitrile. We custom manufacture nitrile gaskets of all shapes and sizes using our die cutting presses and other related machinery (although we do not fabricate nitrile rubber o-rings or nitrile rubber molding components, or use the trade names Nipol, Krynac, and Eroprene).

Nitrile rubber gaskets chemical and physical properties vary a great deal depending on their composition of acrylonitrile; the greater the concentration of acrylonitrile in the polymer, the greater the final rubber gaskets resistance to certain chemicals will be. However, the nitrile rubber gaskets will become less flexible as the amount of acrylonitrile used increases. This makes nitrile rubber very resistant to diesel, grease, oil, gasoline and other chemicals, and we advise nitrile rubber gaskets for use in applications where components are exposed to chemicals on a regular basis.