EPDM Rubber Gaskets

EPDM (ethylene propylene diene monomer) rubber is best known for its superior resistance to most harsh and toxic chemicals, and although this material has great chemical resistance, it is not recommended for use in sealing environments that are exposed to:

- Oil

- Gasoline

- Kerosene

- Aromatics

- Aliphatic hydrocarbons

- Halogenated solvents

- Concentrated acids

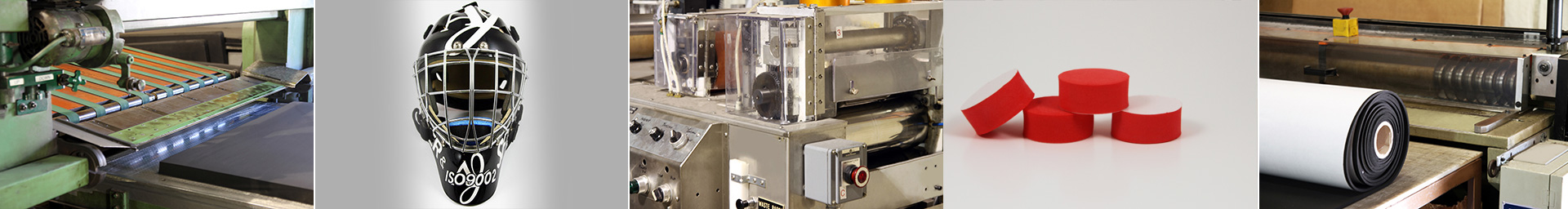

A.J. Rubber & Sponge Ltd. has the expertise and capability to die cut this EPDM (ethylene propylene diene monomer) to your exact specifications for use as seals or gaskets in any industry. EPDM (ethylene propylene diene monomer) rubber is often incorporated in the process of fabricating weather seals and gaskets, and effectively functions as a source of noise reduction and/or acoustic insulation in the automotive industry. EPDM (ethylene propylene diene monomer) rubber is an excellent source for manufacturing gaskets or seals for use in atmospheric conditions exposed to ultraviolet (UV) light, sunlight, ozone, wind and rain. EPDM (ethylene propylene diene monomer) rubber gaskets can typically withstand temperatures ranging from -50°C to 150°C (-58°F to 302°F).